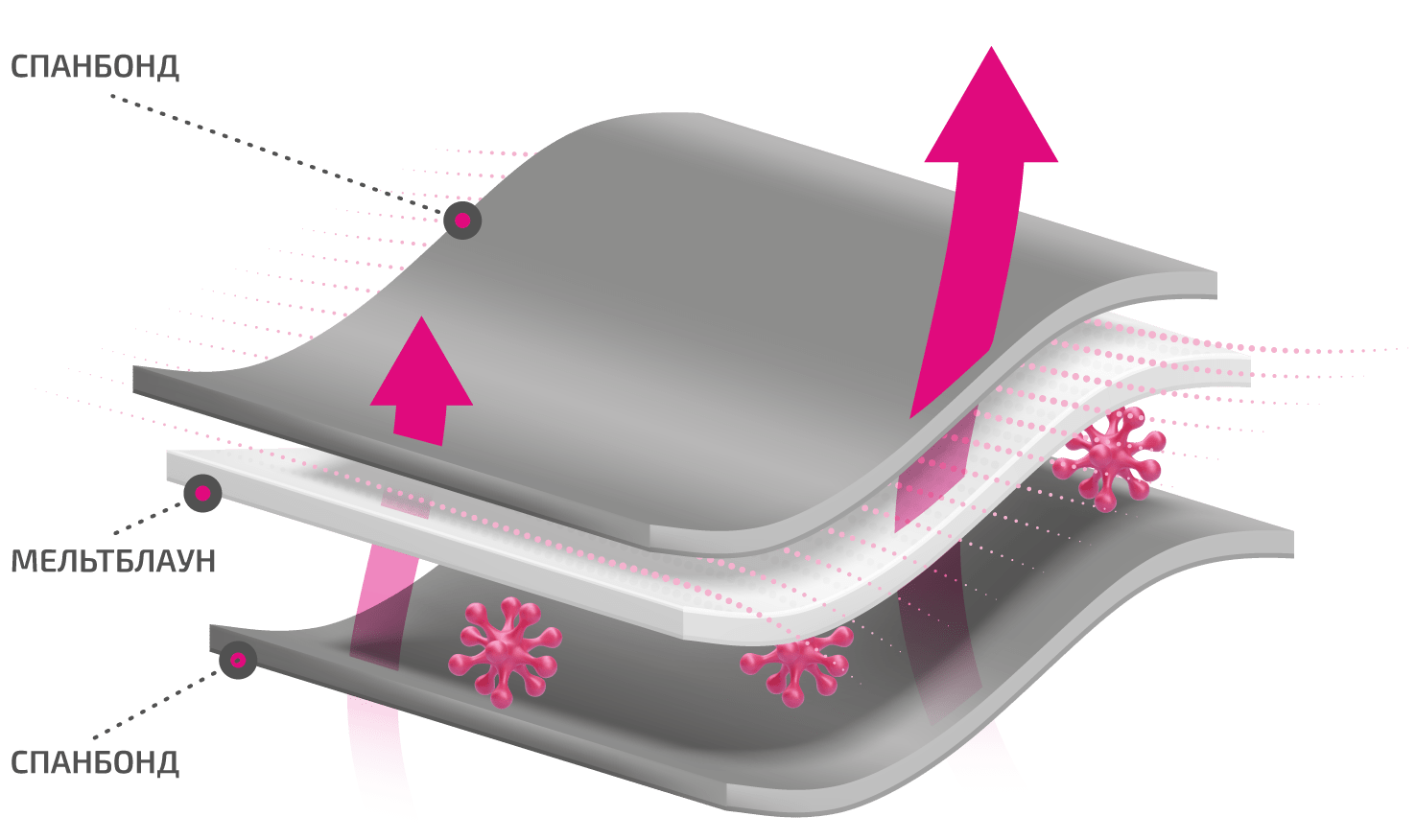

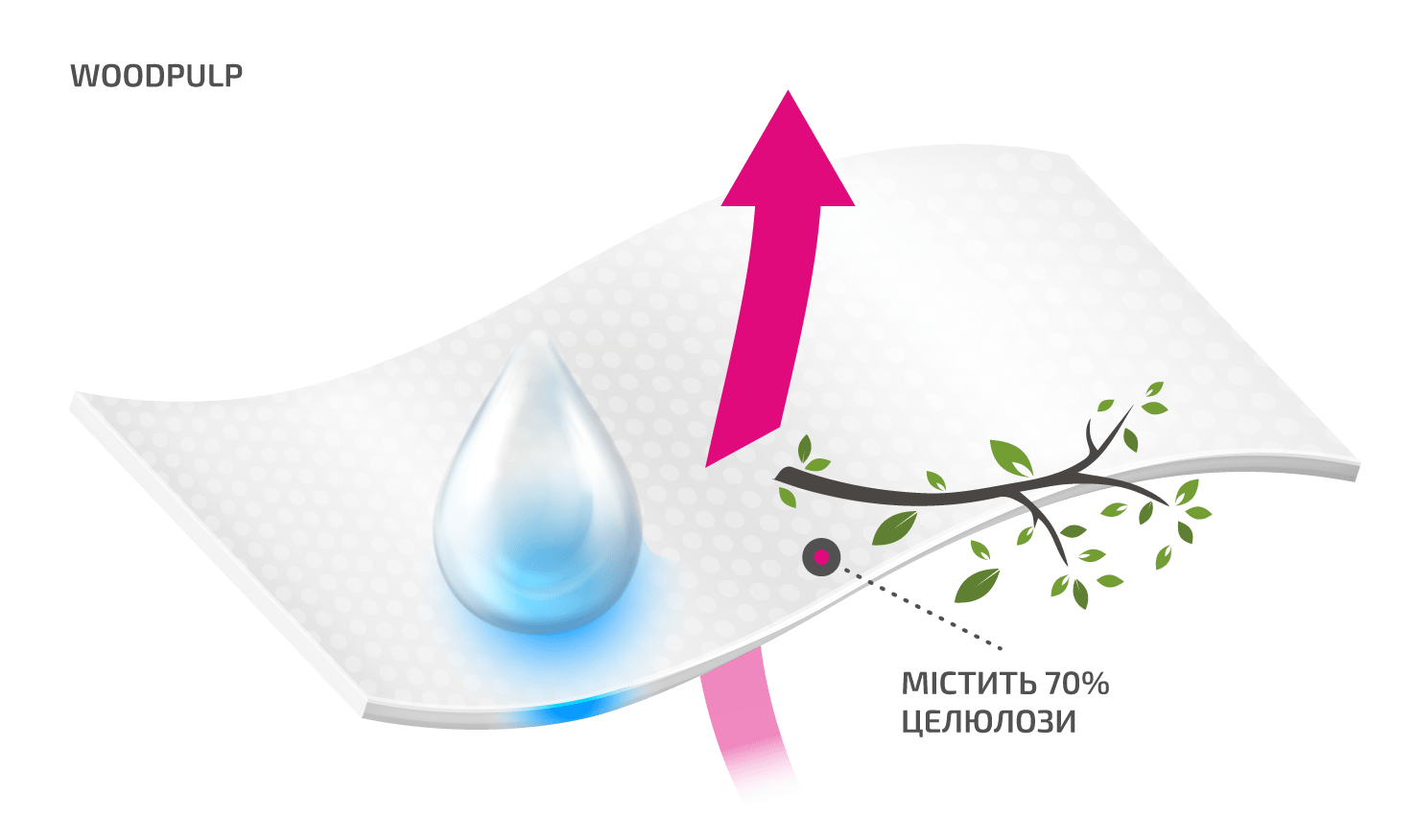

The features of the three-layer structure of the SMS material (spunbond – meltblown – spunbond) allow the upper layers to absorb moisture well and retain it, maintaining breathability.

The presence of a meltblown layer increases the antibacterial properties of SMS compared to single-layer materials by 7-10 times, which is very important for ensuring hygiene.

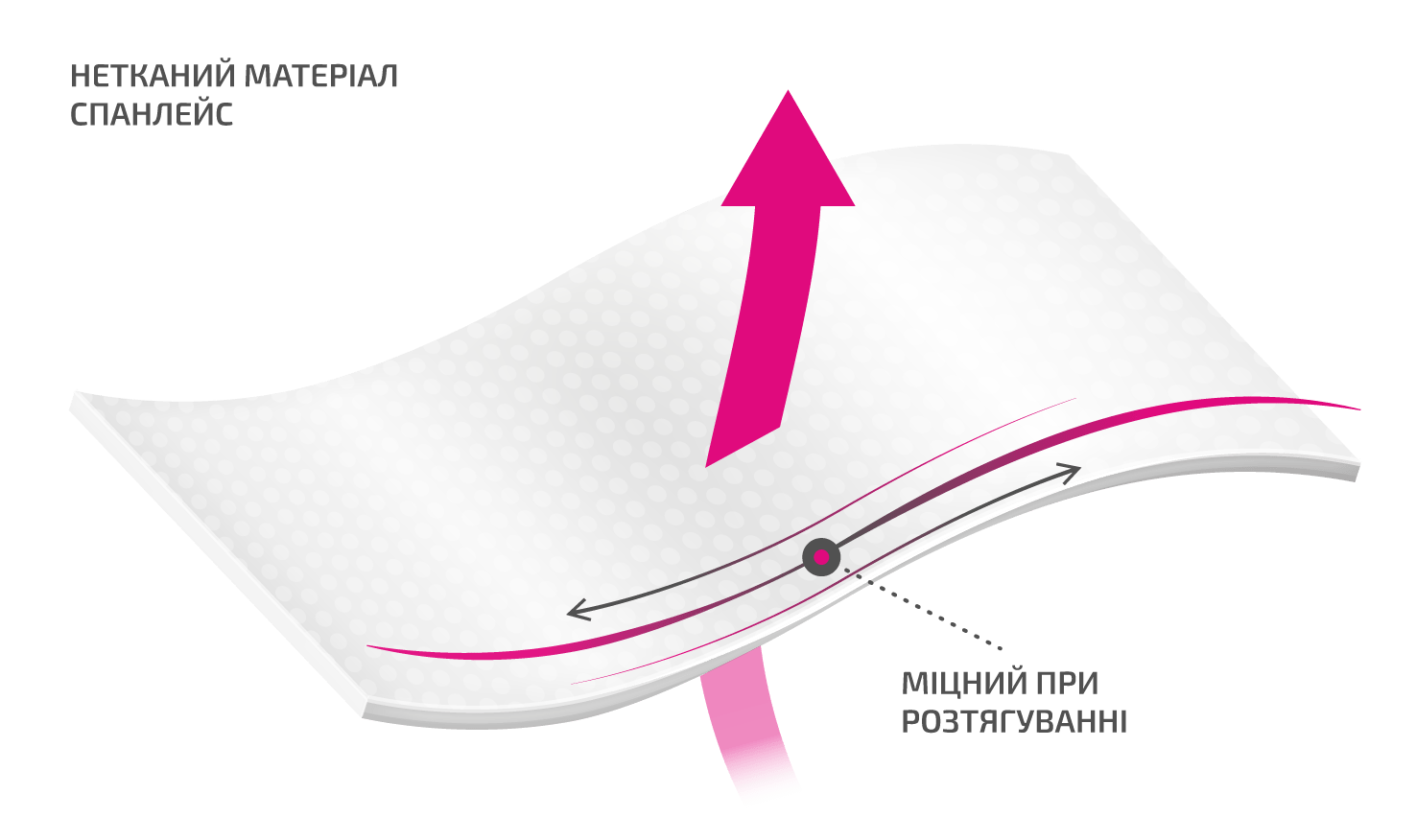

SMS material is widely used in medicine to produce protective medical clothing and surgical masks.

Also, SMS is utilised as a filtering material in various products that require reliable and effective protective functions, such as disposable sheets for the beauty industry, headrests in airplanes and trains, and bed linen sets.

Meltblown and its combinations with other nonwoven materials are characterised by their resistance to the action of common substances, as well as their resistance to fungi and microorganisms.